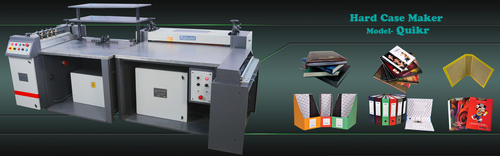

Hard Case Maker-QUIKR

Product Details:

- Product Type Other

- Technology Other

- Power Source Other

- Operating Type Automatic

- Power 440 Volt (v)

- Surface Treatment Coated

- Dimension (L*W*H) h-1100,l-1600,w-1700 Millimeter (mm)

- Click to View more

Hard Case Maker-QUIKR Price And Quantity

- INR

- 1 Box

Hard Case Maker-QUIKR Product Specifications

- Gray & White

- 400 Kg/hr

- 1

- Other

- Other

- 1000 Kilograms (kg)

- 440 Volt (v)

- Diary,Register,Box/Spring File

- h-1100,l-1600,w-1700 Millimeter (mm)

- Coated

- Other

- Automatic

Hard Case Maker-QUIKR Trade Information

- MUMBAI

- Cash Advance (CA)

- 2 Box Per Month

- 30 Days

- Contact us for information regarding our sample policy

- Wooden Box

- Western Europe Middle East Africa Asia

- All India

- ISO

Product Description

Technical Specification :

|

Maximum Case Size |

32 x 22 |

|

Minimum case size |

3 x 3 |

|

Board Thickness |

1 to 6 mm board |

|

Paper Thickness |

60 to 300 gsm flexible paper |

|

Turning-in flap size |

15 to 25 mm (Depending upon the paper quality) |

|

Production |

200 to 250 cases / hr |

|

Glue |

Hot & Cold (Optional) |

|

Gluing System |

Paper Bottom |

|

Man Power |

Three Operators |

|

Power |

3 Phase, A.C. Motor, 2.75 kw, 440 VAC, 90 Hz |

|

Dimension |

Gluing Unit -H-1200xL-1480 x W-930 mm |

|

Dimension |

Folding Unit -H-1000xL-1500 x W-1600 mm |

|

Dimension with wooden Pack |

Gluing Unit -H-1300xL-1550 x W-1000 mm |

|

Dimension with wooden Pack |

Folding Unit -H-1100xL-1600 x W-1700 mm |

|

Total No. Of Box |

Two |

Economic High quality Multi-use

Hard Case Binding Machine: Vallava Innovative design is QUIKR model hard case maker machine it is a heavy duty construction machine makes sure of consistent high quality PLC based multi product Hard Case Binding machine. This Modular single BRUSH TURNING cum PNEUMATIC TURNING unit machine is suitable for book binders, printers and bulk stationery manufacturers like Box file Mfrs., Notebook Mfrs., and Diary Mfrs. etc. QUIKR model is also designed for variety of case binding jobs, as demanded by the market.

Modular Binding system : The Binding system provides the facility for

- Four Side fold in Pneumatic system or

- Four Side fold in brush turning unit or

- Two side fold in Pneumatic system and two side fold in brush turning unit.

- Only calendaring shall be possible by setting on single direction mode While inner pasting.

- Special program made for paper box Mfrs.

Reliable and Proven Gluing system : 20 Inch long Stainless Steel glue rollers are used for proper constant bottom glue application. The machine has high speed paper feeding system & single operator gluing units. Operator can operate the machine without touching the glue and this will protect the case from dust accumulation. Cartridge type glue tank with separate hot water tank is provided. Precise control of paper releasing tension blades for proper paper release and high speed run helps in avoiding the paper stuck / roll in the glue rollers. It has the maximum high speed paper feed system of this kind in the market at present.

High speed Single Brush-Turning System : The Single station brush turning unit completes the turning in for all Four sides (by Passing Two time). Rollers & brush will rotate to fold the flap within few seconds by reverse & forward system. The PLC based reverse forward rotating facility is provided to the Silicon Rollers and brush. There is a PLC technology for rapid high speed operation. Ultimately manufacturing of (inner pasting) Files Table Top Calendars, conveyor and all rollers shall be operated in single direction by program.

Unique Dust-free Calendaring System: Quality Silicon rollers are used in the calendaring unit, which can be cleaned easily. Fine rollers control knob-cum-locker is provided for constant disengagement of upper rollers. This is to ensure that case is free from glue and dust on front side especially when using costly wrappers like white paper, wedding card products, quality binding clothes etc. It is a major requirement of Hard Case Binder today.

Flexible conversion for high productivity: Variable speed gluing application system, glue thickness adjustable system, double side gauge unit, Paper table, automatic & variable timing Pneumatic turning unit, heavy duty silicon rollers to press calendaring for super finishing hard case cover. All Three Operators can comfortably sit & work. Gluing / brush turning and pneumatic turning this three operation can produce more than 300 hard case per hour comfortably.

Machine Users :

- Publication Book Mfrs

- Wedding Card Mfrs.

- Note Book Mfrs.

- Wedding Album Mfrs.

- Bulk Stationery Mfrs.

- Exam Pad Mfrs.

- Box File Mfrs.

- Table Top Calendar Mfrs.

- Product Album Mfrs.

- Book Binding units and

- Paper Box Mfrs.

- Offset Printers etc.

Products :

- Diaries

- Exam Pads

- Registers

- Box Files

- Hard Case Books

- Wedding Invitation cards

- Hard Case Note Books

- Table Top Calendars

- Wedding Album

- Game Boards

- Product Albums

- And Puzzle Boards etc.